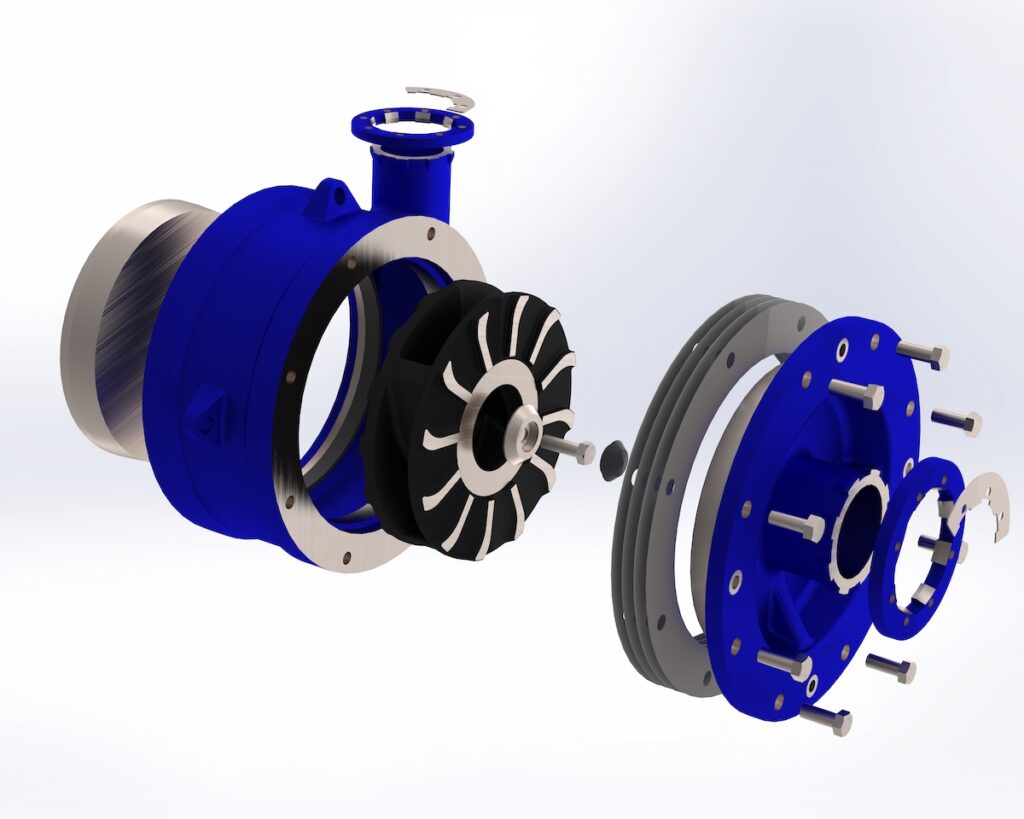

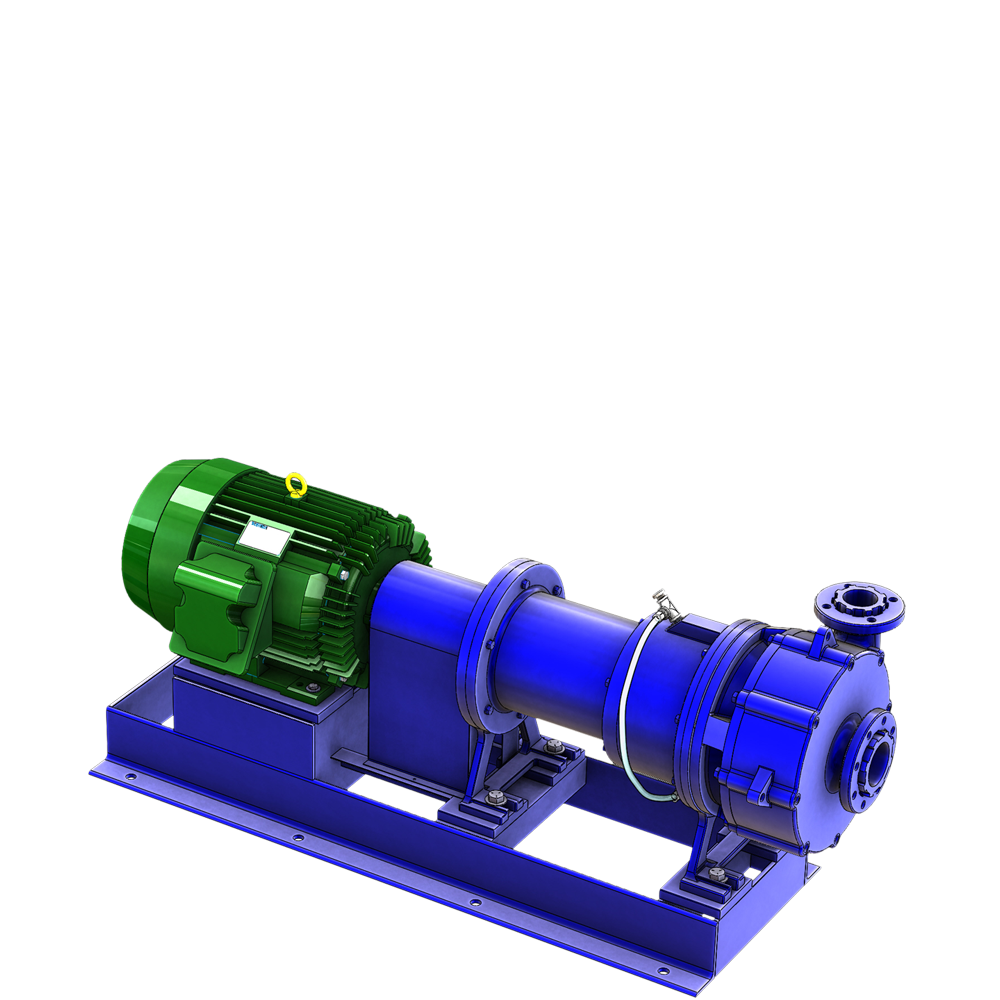

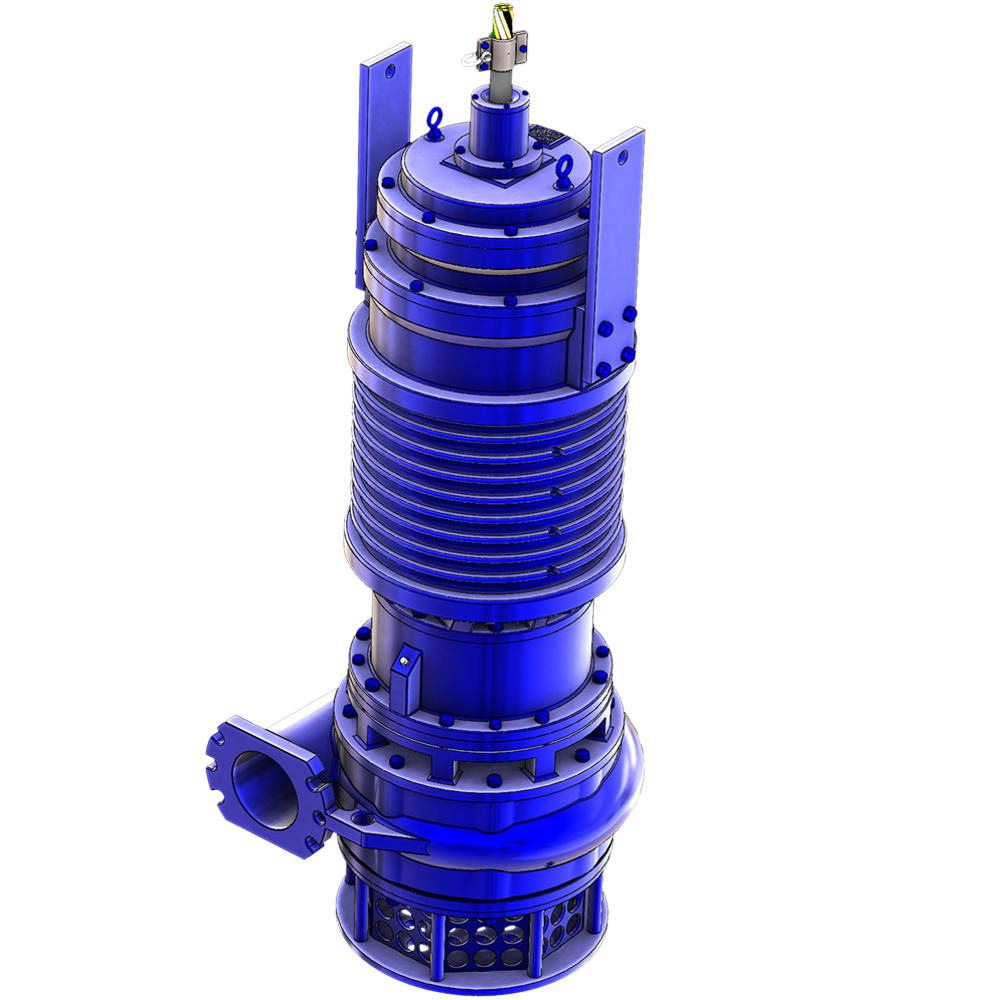

Do you have an application that doesn’t have vertical space for a standard submersible pump? Does your application regularly flood? The GPM-Eliminator™ MonoBloc Pump configuration has a submersible-rated motor to effectively handle contact with water. There is no more worrying about alignment issues because it’s not the standard horizontal configuration. These pumps are mounted on a stand or two feet and a baseplate. GPM-Eliminator MonoBloc Pumps are built to persevere through your toughest applications.

Available options:

- Site Glass on Oil Chamber

- Explosion Proof

- All stainless steel construction

- Various shaft alloys (304SS, 316SS)

- High Chrome Fittings – Elbows and Reducers