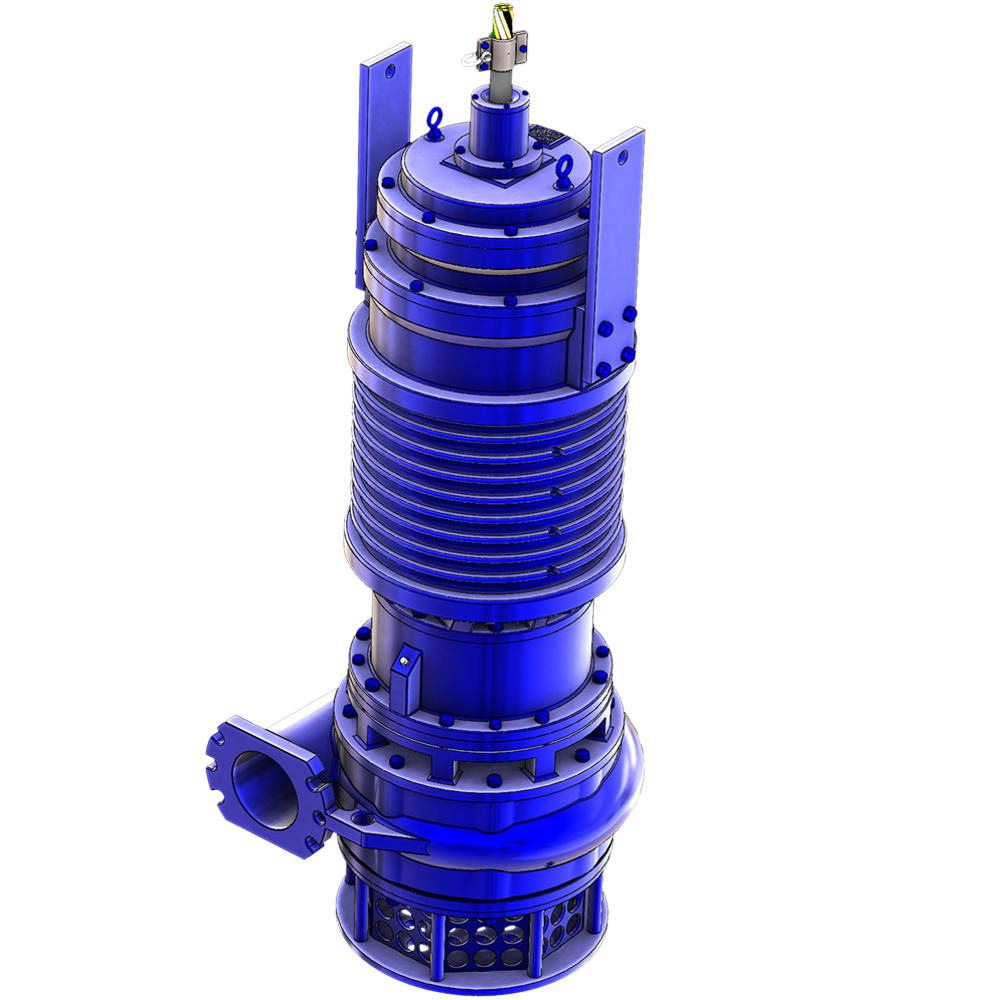

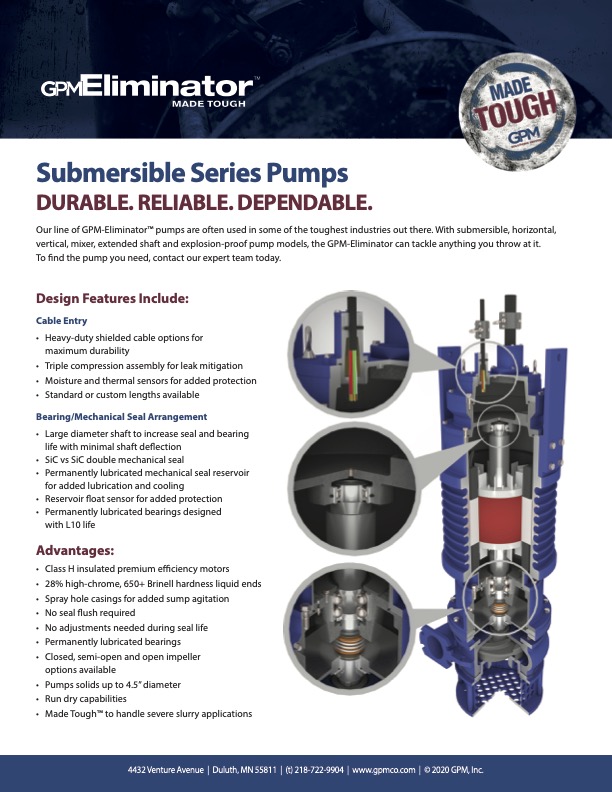

GPM-Eliminator™ Submersible Slurry Pump is engineered to eliminate repetitive pump failures that cause high maintenance, operating, and repair costs. Our heavy duty submersible line of slurry and dewatering pumps provides years of savings while pumping anything from Taconite pellets to clean water. The GPM-Eliminator’s versatile and robust design ensures dependable performance and extended longevity.

The GPM-Eliminator Submersible Slurry Pump is designed and built to tackle your most challenging applications. Ready for a pump that saves time, money, and maintenance work? Our American-made submersible slurry pumps are delivered in just weeks!

Submersible Add Ons:

- All stainless steel construction

- Shaft agitator/ spray ring for thick slurries

- Longer cable lengths are available

- Various shaft alloys (304SST, 316SST)

- Sump control panels with level control

- Explosion Proof Options Available:

- 15hp 4 pole

- 20hp 4pole